-

0

Years Of Experience

-

0

Employees

-

00

Workshops

-

00

Product Lines

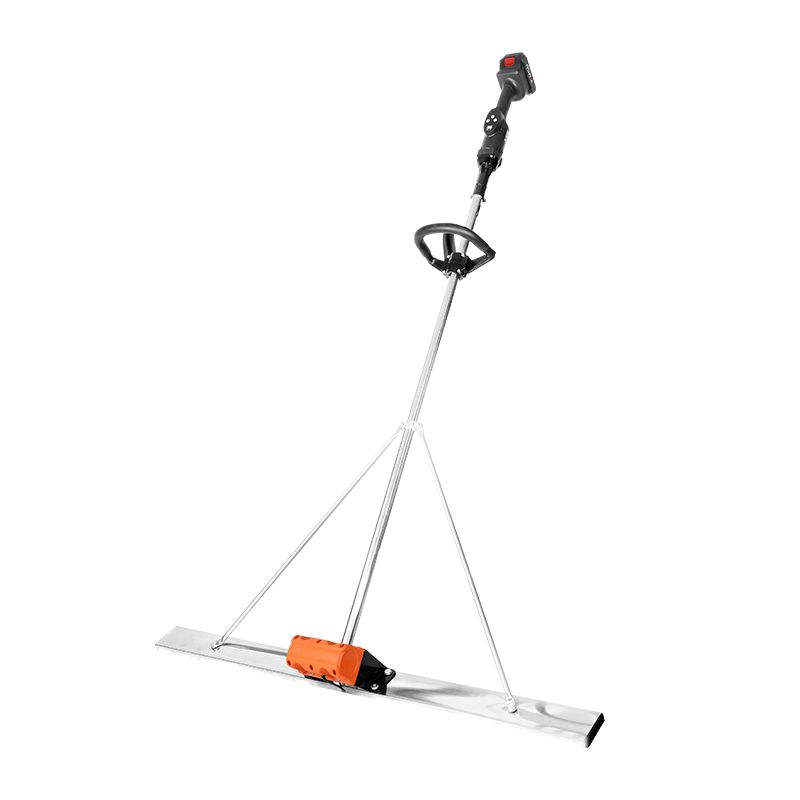

Custom Cordless Rebar Tying Tool Manufacturers and OEM Suppliers in China

, the company has built a perfect industrial production base,so far it has covered an area of 40,000 square meters,its floor area is 35,000 square meters;it owns a modern industrial plant and the first-class production and testing equipment;at the same time, it has a group of professional senior engineers,a team which includes the middle and high ranking managerial staffs and technicians;it has more than 150 employees now.

EN

EN  English

English Español

Español Deutsch

Deutsch

2024-10-18

2024-10-18